The Premier Concrete Mold Company

Stepping Stone Molds for sale.

Specialized garden stepping stone molds, where you can easily make your own stepping stones using our 100%reusable molds.

If you are looking for a rewarding garden DIY project this is the place to be. they all come with printed instructions on how to use them to produce Garden Path Stepping Stones and cast stone plaques,with our reusable low cost stepping stone molds.

-

Sale!

Square Paver Mold – 15.7″ x 15.7″

Original price was: $69.$35Current price is: $35. -

Sale!

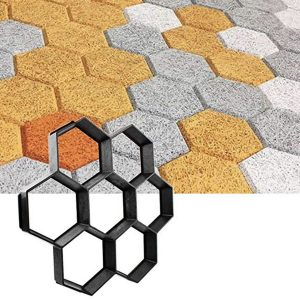

Hexagon Paver Mold | Hexagon Shape Concrete Mold

Original price was: $69.$35Current price is: $35. -

Sale!

Irregular Shape Paver Mold – 17″ x 17″

Original price was: $77.$39Current price is: $39. -

Sale!

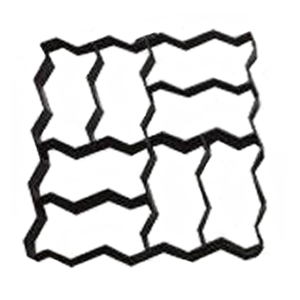

Zig Zag Paver Mold – 15.7″ x 15.7″

Original price was: $69.$35Current price is: $35.

Welcome To The Concrete Mold Shop

If you are looking for a cost effective way to create a garden walkway, stepping stones or patio area …. we have the solution.

EASY DIY PROJECT

Super practical garden concrete mold that will help you create a sensational walkway or patio area easily and quickly

HEAVY DUTY & REUSABLE

Garden stone molds are made from heavy duty polycarbonate plastic and can be re-used over and over agin … right after you pour your first graden steppig stone

INCREASE YOUR PROPERTY VALUATION

Increase the value of your property with beautifully created landscaped walk ways and path ways and patio areas without the huge expense of emplying trades people

The Most Search Terms On Google (18-61)

the mold store | paving stone mold | paving stone molds | cement paving molds | cement paver molds | concrete paver molding | concrete mold paver | concrete pavers molds | concrete paver molds | paving mold concrete | concrete paver form | concrete paving molds | cement pavers molds | molds for concrete pavers | paver molds for concrete | cement pavers mold | concrete mold for pavers | concrete pavers molds for sale | paver molds for sale | concrete paver molds for sale | hexagon pavers concrete | hexagon concrete paver | concrete hexagon pavers | concrete paver mold | octagonal pavers for sale | concrete mold for driveway | patio paving mold | reusable stepping stone molds | stepping stone molds for sale | reusable concrete molds | stepping stones molds for sale | concrete forms stepping stones | moulds for stepping stones | concrete forms for stepping stones | stepping stone concrete forms | molds for paving stones | concrete molds for stepping stones | reusable concrete mold | moulds for concrete stepping stones | concrete molds stepping stones | stepping stone cement molds | best concrete molds | concrete stepping stones molds | cement molds for stepping stones | plastic molds for stepping stones | concrete stepping stones forms | forms for concrete stepping stones | cement molds for gardens | stepping stone molds | square concrete molds | square concrete mold | paving mold | walkway molds | walkway molds for concrete | cement molds for pathways | sidewalk molds | concrete walkway molds | cement walkway molds | walkway mold | concrete mold walkway | pathway cement molds | cement mold walkway | concrete paver molds sale | concrete mold pavers